HOW MUCH DOES A TRUCK SCALE COST in 2025?

As you consider the purchase of a new truck scale, price is often-times one of the first considerations. As with many large equipment purchases there are many models and options which will impact the cost. So, how much do truck scales cost? The short answer to how much does a truck scale cost is $50,000 - $100,000.

First, let’s start with the initial purchase price of the truck scale. Generally, truck scales are sold by independent scale dealers spread across the country. Most truck scale dealers will represent a number of different scale manufacturer brands. Some common brands you will hear about: Rice Lake, Cardinal, B-Tek, Mettler Toledo, Emery Winslow, Fairbanks, Thurman, etc. Your scale dealer can help guide you to the brand which will best fit your budget and application. Checkout this blog post when considering steel deck vs concrete deck truck scales.

PRICES FOR NEW TRUCK SCALES:

The standard truck scale system in the industry is an above ground electronic 70ft long & 11ft wide steel deck. We will use that as the basis for pricing. We will also focus more on electronic scales vs hydraulic. There are a lot of things to consider when pricing your scale.

There are two main packages you can choose from; a basic package or a turnkey package:

1. BASIC TRUCK SCALE INSTALLATION:

Equipment: This will include the truck scale weigh bridges, load cells, basic indicator, printer, and any other accessories you order such as a remote display.

Foundation: This will not include the truck scale foundation. You will need to coordinate for forming and pouring the concrete foundation. The truck scale manufacturer will provide foundation drawings for you to use. This will save you on cost. The downside is that pouring foundations for truck scales can be difficult and requires it to be within ¼” per the drawings. Bottom-line, ensure your concrete contractor is high-quality. Pouring a truck scale foundation is more technical than just pouring a slab for a house or garage. To learn more details on truck scale foundation types checkout this blog post on build timelines.

Installation: This will include setting the truck scale on the foundation with a crane after it arrives via flatbed truck. It also includes anchoring the truck scale, running all wiring, installing all load cells, and calibrating the scale. Finally, the scale service company will complete state weights & measures placed into service paperwork. To learn more details on the installation checkout this blog post.

Truck Scale With Basic Installation Average Cost: $55,000 - $80,000

2. TURNKEY TRUCK SCALE INSTALLATION:

Equipment: This will include the truck scale weigh bridges, electronic load cells or analog), basic indicator (stainless steel or washdown), printer, junction box, and any other accessories you order such as a remote display.

Foundation: This will include the truck scale foundation. Included is basic site preparation, digging of piers, along with layout of wash-out slab. The concrete is normally poured over 2 days. One item to note is whether to add concrete ramps to your project or not, these can add over $10,000 in additional cost but are often necessary. Keep in mind that there are regulations on the steepness of the ramps; these rules are normally set by each state weights & measures department.

Installation: This will include setting the scale on the foundation with a crane after it arrives via flatbed truck. Includes anchoring the scale, running all wiring, installing all load cells, and calibrating the scale. Completing state weights & measures placed into service paperwork.

Truck Scale With Turn-key Installation Average Cost: $95,000 - $125,000

To see what truck scales American Scale offer click here.

Steel Surcharges

As of early 2021, many truck scale manufacturers are implementing steel surcharges on their truck scales. This is due to surging steel pricing across the county as the pandemic has waned. These surcharges range from 5% up 15% depending on the specific manufacturer. This can add thousands to your truck scale project. A concrete deck truck scale may save some money as they contain less steel. However, keep in mind the scale decks often require rebar and the price for rebar has also increased dramatically.

Freight

The prices above do not include the freight cost to ship the scale to your location. There is significant variability in freight pricing based on your location in relation to the scale manufacturer’s factory. Also if the scale is 12 ft or wider it will often require escort cars the entire trip which increases the cost. Some scale companies will quote fixed cost freight but most will provide an estimated freight cost range given the trucking spot rates change by the day.

Truck Scale Freight Average Cost: $2,500 - $4,500

Truck Scale Add-ons / Options:

There are number of truck scale accessories or options that you may need or be required to purchase. For example if you operate a truck scale in a location that is under the Mine Safety & Health Administration (MSHA) jurisdiction then you must have double-pipe guide rails on your truck scale, period. Or in most states the requirement is that for legal for trade truck scales you must have a scoreboard or remote display that a truck driver can see from inside their truck. To learn more about when a remote display is required checkout this blog post.

Other Considerations

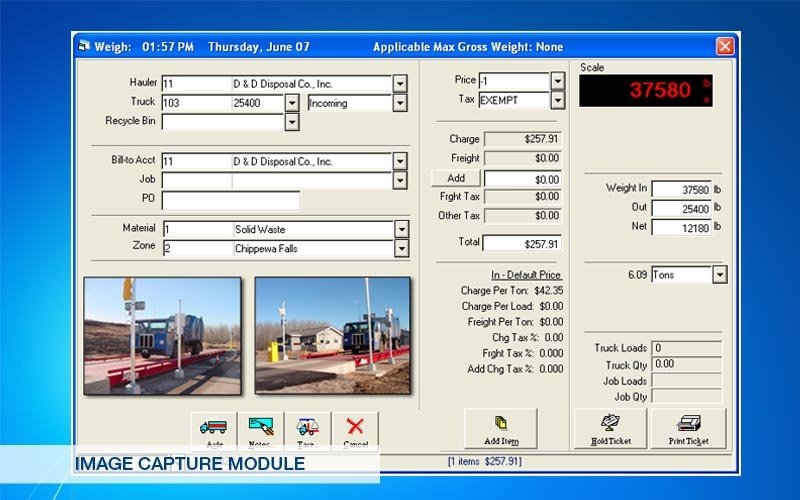

Also you need to consider whether your scale will require connectivity to a network or computer system. You need to ensure your scale indicator has the necessary output built in to send the data whether ethernet, fiber optic, USB, serial, etc. We have a scale accessories page that can help you find what you need.

Bottom-line, make sure account for these additional options when computing the price for your new truck scale. During the lifespan of your scale ownership you will find that you may need certain accessories to add a level of ease added to your operation. These options are where you should lean on your scale dealer to assist as they have years of experience.

NOTE:

When considering the purchase price of a truck scale project, you need to also understand the long term costs associated with the scale. Understanding the weighing applications that will be used will definitely help you narrow down cost. These range from warranties, truck scale calibration costs, and general maintenance that will be required, to just wanting to know the differences between truck scales. Your scale dealer is your best source of information on these items. Be sure to ceck out our post about issues that can occur with truck scales. To learn more about truck scale warranties, check out The Guide To Truck Scale Warranties. Our Common problems with truck scales is a good article to look into as well.