Analytical Balance: What Are the Uses?

Most people have never had the requirement to use more than the basic weighing function of a scale. However, many weighing balances are capable of much more advanced functions which can simplify a variety of complicated tasks. This article presents an informative summary of some of the main functions of weighing balances, enabling you to get the most out of your weighing balance.

What is a Weighing Balance?

A weighing balance is an instrument that is used to determine the weight or mass of an object. It is available in a wide range of sizes with multiple weighing capacities and is an essential tool in laboratories, commercial kitchens and pharmacies. To learn more checkout this blog post.

What is the difference between a Precision and Analytical Balance?

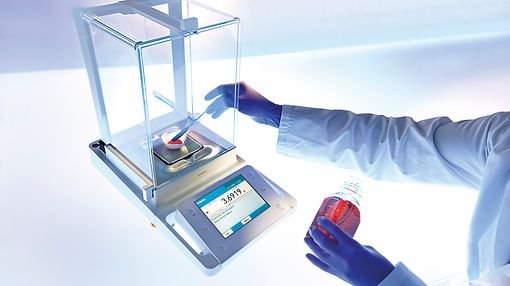

Precision and analytical balances are specific types of weighing balances which measure much smaller masses than the average scale. An analytical balance is the most precise because it has a higher readability, measuring to the nearest 0.0001g. Analytical balances usually include draught proof weighing chambers for precise measuring of mass and are often used alongside anti-vibration tables to increase accuracy. A precision balance on the other hand typically measures to the nearest 0.1-0.01g but has higher capacity. Both can measure capacities from hundreds of grams to kilograms.

What are the Main Weighing Balance Uses?

Balances are generally more sophisticated and precise than scales and are therefore commonly used by professionals for advanced scientific weighing in the following industries:

- Pharmaceutical

- Educational

- Food and beverage

- Chemical

- Industrial

Due to their high precision and advanced technology, precision and analytical balances are used in laboratories to efficiently perform specific tasks such as weighing test materials and sampling amounts, formulation, density determination, purity analysis, quality control testing and material and conformance testing. These analytical balance functions will be explained in detail in this article. Balances with higher capacities are not only used in laboratories but can be used to test larger high-capacity weighing materials such as in construction sites.

Function : Formulation

Description: Formulation (AKA recipe calculation) is a selectable weighing mode that is available on more advanced precision and analytical balances. Formulation enables the user to store, add and calculate the weights of multiple ingredients, providing a total weight value. Formulations must be repeatable, so it is critical to accurately weigh each ingredient or component and ensure the proper ratio of each within the formulation. Many semi-micro, analytical and precision balances offer both simple formulation and database formulation, which can be used to store custom formulae and recipes, making it easy to recreate a formulation. Formulation can be used in a wide variety of weighing balance applications, including in pharmaceutical labs, research and development labs, new product development, food production, beer brewing, paint mixing and even mixing ink for screen printing.

Function: Density Determination

Description: The accurate determination of the density of a substance is a critical part of the research process in sample analysis. Density is also an important parameter in quality control, as variations in the density of a solid for example can indicate air pockets that could jeopardize the integrity of the material. Similarly, a change in density could indicate that a liquid or solid is impure and contains contaminants. Calculating density seems straightforward as it simply involves dividing the mass of the matter by its volume. However, in practice, this process can be complicated, tedious and inaccurate. Luckily, density can be determined much more quickly and easily using an analytical balance, using a variety of available methods. One of the most popular methods is the buoyancy technique, which can be carried out in the straightforward manner of using an analytical balance fitted with a special density kit. The most common setup involves a beaker placed on the balance with one weighing pan above the beaker and another suspended inside. The beaker is filled with a reference liquid of known density such as water, ethanol, and sodium chloride solution. The basic steps involved are to weigh the sample in air, then weigh the sample again in the reference liquid and finally calculate the density based on these measurements.

Function: Quality Control Testing

Description: Quality checks that include weighing must be applied to random samples from every production batch. Ten or more samples should be weighed and each piece has a correct weight, so the measurement must fall within these tightly defined tolerances and the scale must not show any abnormalities. Therefore, a highly accurate and reliable balance is required. Quality control tests can be carried out using plus and minus weighing, which is a very simple weighing function that is possible on any scale that has a TARE function and supports negative weight values. It is ideal for comparing items to a known weight for quality control purposes. Each scale works differently, but the basic procedure involved placing a weight or sample on the scale that weighs the ideal amount or target weight and pressing TARE to zero the scale. The original sample must then be removed and the samples added to be checked one by one. This will result in the scale displaying the deviation (positive or negative) from the sample weight.

Function: Parts Counting

Description: A common challenge in the manufacturing or packaging industry is determining whether or not the number of parts in a batch is accurate. The traditional way is to count them by hand, which is time consuming and can entail human error. Using a balance however can make the process faster and more accurate. Parts counting is an advanced feature that is available on a variety of scale types, allowing the loading of a collection of identical items onto the scale and the automatic counting of how many are present. The feature works by supplying the scale with a sample of the items to be counted so that it can work out the weight of a single unit. It then uses this value to count items quickly. This is used extensively in quality control applications for counting manufacturing parts or for counting finished products quickly.

Function: Dynamic Weighing

Description: Dynamic weighing refers to the weighing of moving objects such as animals. It is often necessary to weigh live animals to adequately monitor their health and baby animals must be weighed frequently to ensure that they grow up healthy. The dynamic weighing feature on a balance can take accurate measurements when the subject is moving. Dynamic weighing works by measuring the average weight based on the force exerted by the animal over an extended period of time. Once the internal calculation is completed by the balance, it will hold the value

For more information about any of the above balance functions, or to find out which weighing balances could benefit your business, contact a member of our team today. We would be happy to help. Checkout the balances we offer here.

Closing Words

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.