We are often asked what are the differences between a full size, say 70ft truck scale, and an axle scale. There are few key features that differentiate an axle scale from its large brother.

What is an axle scale?

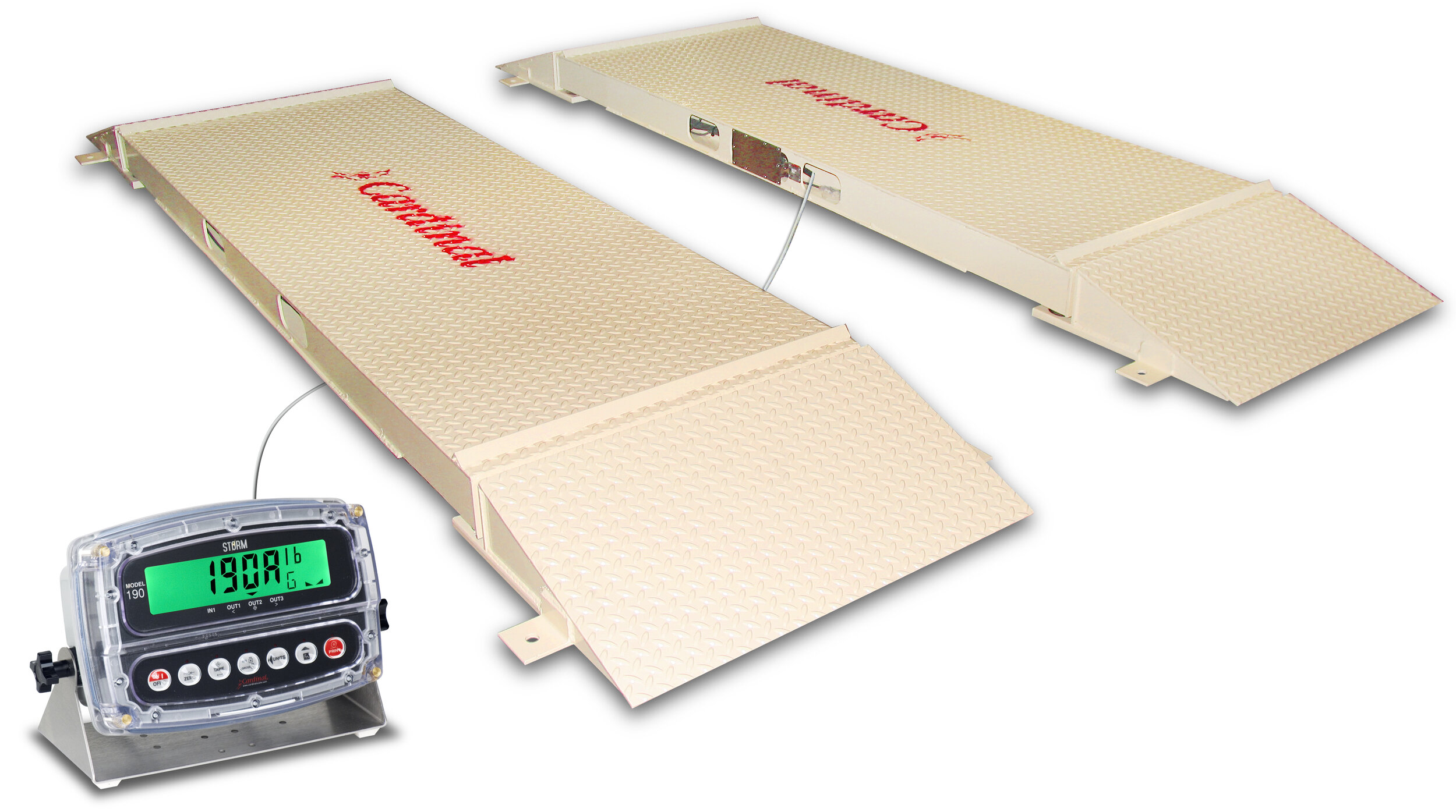

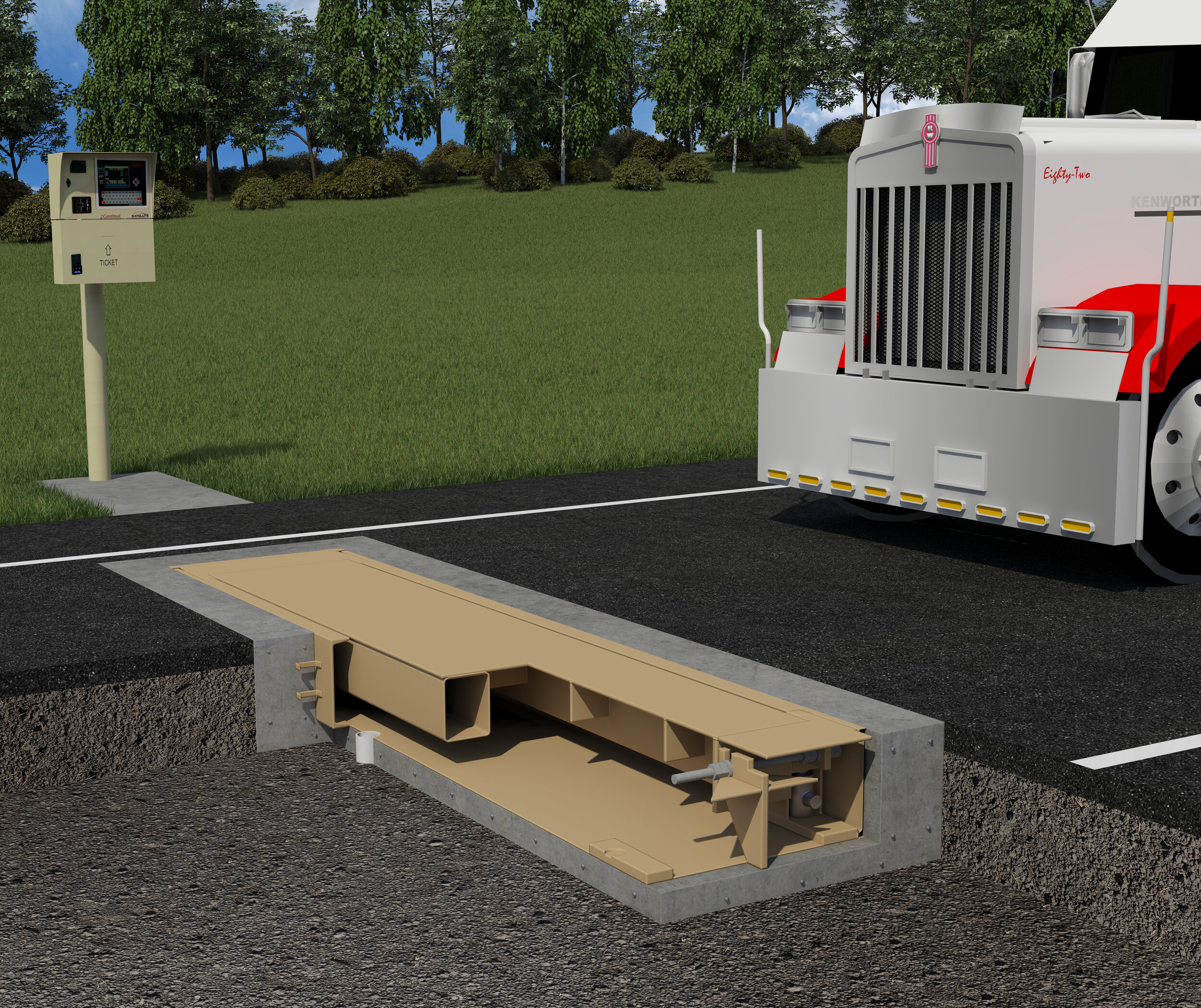

As the name implies an axle scale is a weighing system designed to weigh the individual axle groups. The weighments are completed one axle set at a time and then all the axle weights are summed to provide the total gross weight of the truck. This is much different than a full size truck scale where the entire truck is weighed at one time.

Legal For Trade:

If you are using your scale in any legal for trade weighing operations then an axle scale cannot be used. Axle scales are not considered Legal For Trade. This is because as each axle group is weighed individually there are slight errors and therefore the overall accuracy of the scale is not within national testing standards. Bottom-line, if you are looking to weigh trucks legal for trade then you cannot use an axle scale.

Benefits of an axle scale?

Although axle scales cannot be used legal for trade they work well in many situations. They are great for gathering weight data to ensure trucks don’t leave a facility overloaded per DOT standards. They also take up significantly less space than a full size truck scale. This is a huge advantage for facilities with limited real estate to locate a scale. The footprint for an axle scale is only 33% of a full size truck scale. Axle scales are also more economical. This is because the scale itself is much smaller and requires less materials to construct. Similarly, any concrete foundation work is much less with an axle scale vs a full size truck scale. Finally, not all axle scales require installation requiring concrete foundations. Many can be installed on existing flat pavement and are therefore easier to install and move in the future if needed.

Axle Scales & Weigh-in-Motion?

A unique benefit of an axle scale is their ability to offer weigh-in-motion. This means the truck does not have to stop on the scale, instead they drive over it at a slow speed and the scale does the rest. Although the accuracy is slightly less, weigh-in-motion provides operational benefits since more trucks can be weighed faster since each truck does not have to stop. Most weigh-in-motion axle scales boast 1-2% accuracy. Keep in mind that not all axle scales offer this feature. Many axle scales are simply static scales that sum of the total axle weights at the completion of all axle groups being weighed.

Popular Axles Scales

There are a number of manufacturers of axle scales. Of note is InterComp Scales, B-Tek Scales, and Cardinal Scales. Each has their own models and options; see below for a few popular ones. Also checkout our Axle Scale page.

Intercomp

B-Tek

Cardinal

Closing Words

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.