Purchasing a forklift scale can dramatically increase efficiency and throughput by weighing materials onboard a forklift during the material handling process. Since there are many models and classes of forklifts, it’s important to select the correct forklift scale attachment for your current equipment.

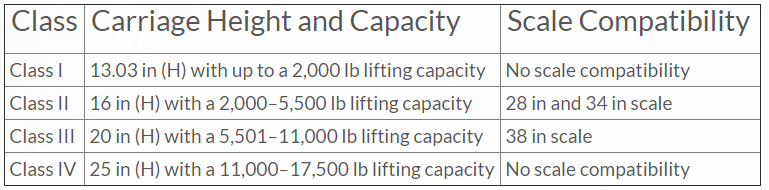

Forklift scale compatibility is determined by the ITA Class of Carriage that is installed on the forklift. An accurate measurement is required to ensure the correct scale attachment. To provide some guidance, the lifting capacity of the forklift can determine the class type of carriage:

Class Carriage Height and Capacity Scale Compatibility

Plan a Visit

It is important to have an American Scale representative visit your site to understand how the operators will use the forklift scale, the type of forklifts you use and if any attachments already exist.

Select the Scale

An American Scale technician will measure the width and height of the forklift load apron and use the scale manufacturer’s product drawings to determine the appropriate scale size.

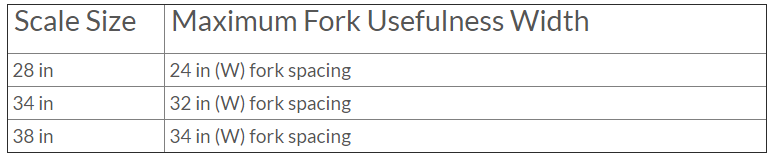

Depending on the width of the scale selected, make sure the operator can continue to use the forklift with the forks having the maximum useful width.

Consider how the change in fork length from the original forklift will affect operations. The forks will usually protrude an additional four to five inches. Make sure the operators can accommodate this additional length in their day-to-day use.

Make sure the forks are removable from the load apron. If not, it may be an attachment. If an attachment is going to be installed on the scale, make sure the mounting plates on the attachment will fit onto the front of the forklift scale. Use the width measurements from the scale’s specifications to ensure adequate space. During installation, some attachments may require calibration with standard forks prior to installing the attachment if there is no method available for calibration using the forks.

Observe how your forklift scale is going to be used.

Is there potential for static buildup due to a painted floor?

Is it a washdown application? Not all electronic forklift scales are washdown.

If using a three stage mast, the wireless battery option may be best suited to reduce wear on the coiled cable.

Ask your operators which functions the forklift scale will need to perform, and ensure you’re covering all your operations. If weighing only or performing a simple accumulation, a basic scale indicator can transmit data to an RS-232 printer via a print button, continuous output or optional Wi-Fi.

Identify the battery type on the forklift and ensure your forklift scale is compatible. Propane or natural gas forklifts operate on standard 12 volt batteries and nine to 36 volt forklift scale will work best. Electric batteries typically range from 36 to 48 volts and are prone to static. Make sure there is a static prevention method installed on the forklift scale when using an electric forklift.

If the load backrest extension is attached to your forklift, ensure the overall width, including flexures, does not create mechanical interference with the scale. If mechanical interference exists, the load backrest may need to be removed or modified. If you’re selecting a wireless cable option for your scale, or a non-coiled cable version, make sure you have access to change the batteries.

Review with your operators the mounting location of the indicator and other peripherals attached to ensure they are within easy view, but do not hinder safe visibility. Other items may need to be mounted, such as handheld scanners or bar code readers.

After the Installation

The forklift will require de-rating and American Scale can assist. The de-rating tag may be an OSHA requirement and you are required to inform the forklift service provider with a request for a new data tag.

For optimal working function and safety, make sure there is a side shift prevention method installed on the load apron. Older forklifts do not have this as a standard feature. Also ask your scale service technician to review with your operators the daily and weekly maintenance items to ensure accurate weighing and performance. These measures include: ensuring the centering pin does not touch, checking for proper gaps on bottom cleats, checking for debris within the scale and between the forklift load apron and forklift scale back plate, and reviewing where electronic components are installed so the operator is cautious when applying grease and cleaning the forklift.

Ask your scale technician to review calibration instructions and the importance of using calibrated weights. It is always a good idea to ensure that any scale meets local Weights & Measures requirements, especially if you will be using the weight readout from the scale for commercial applications. American Scale can coordinate a visit from the local W&M inspector as needed.

For more than 20 years, American Scale has provided the North Carolina, South Carolina, and Virginia regions with industry-leading scale technologies. We offer scale sales, service, calibration and more to key market areas, including Charlotte, Greensboro, the greater Raleigh-Durham, Columbia, Richmond, Blacksburg, and others throughout the Southeastern United States.