A Guide to selecting a wash down bench scale

Scales are used almost everywhere, sometimes in austere conditions or in demanding environments. Washdown scales are designed and built to withstand wet environments and harsh industrial conditions. As the name indicates, these scales have easy cleaning access after use and are constructed to prevent liquids and particles from penetrating internal scale components. Washdown scales are found in various industries and applications.

What does it mean for a scale to be “washdown”?

Washdown DOES NOT EQUAL waterproof. Different scales and electronic components have different protection ratings; these ratings for washdown scales can vary by make and model. Ingress Protection, or IP ratings, highlights the protection rating from elements like water and dust as well as cleaning chemicals. Scales with low IP ratings can generally resist spills or humid environments while scales with higher IP ratings can be washed with heat and pressure.

Types of washdown scales

Washdown scales are generally made of stainless steel and they come in a range of shapes and sizes.

- Bench scales

Washdown bench scales tend to be small to medium -sized. These scales can have capacities around 300 lb and lighter; the readability, or division size, is dependent on the scale capacity. Washdown bench scales are useful in food and beverage, pharmaceutical, specialty chemical and several other industries. The scales are often found in warehouses, laboratories and commercial environments. To see different models of bench scales click here.

- Floor scales

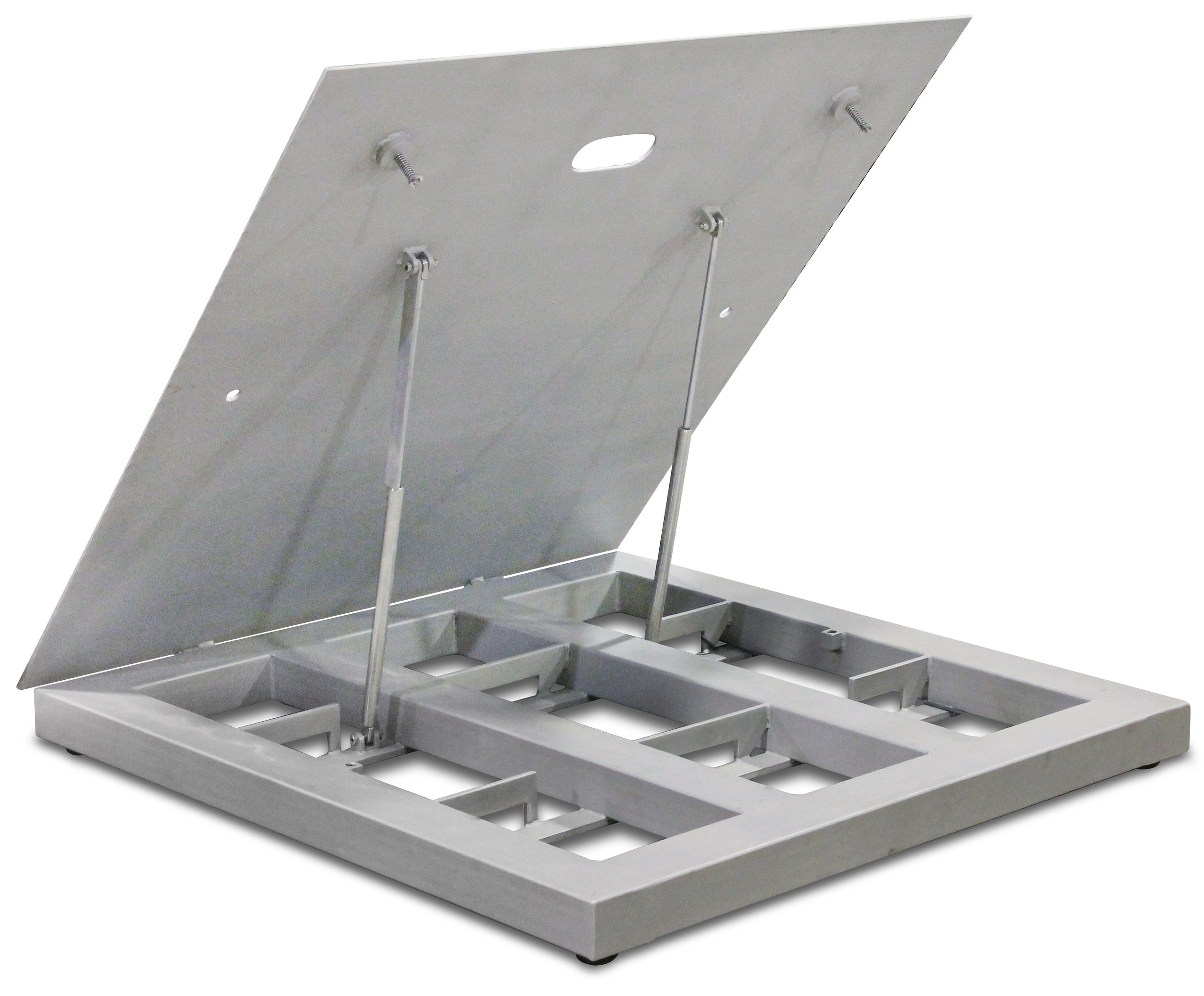

Washdown floor scales are larger than bench scales, usually 3 by 3 and larger. They are durable and handle heavy loads up to 10,000 lb. Washdown food scales are often used in food processing areas, commercial warehouses and dockyards for weighing items in bulk. To see different models of floor scales click here.

- Tank scales

Stainless steel weigh modules and load cell systems can be installed under tank legs for weighing bulk quantities in docks or in food processing facilities. They're built to withstand demanding conditions in harsh environments with sealed components that are protected from water and dust ingress. Tank scales are built with checking to handle stresses from agitators and motors.

- Retail scales

Washdown retail scales are compact and legal for trade. They offer all the usual functions of approved scales, such as a display that shows weight, price per unit and total cost, a rear-mounted display that customers can see, and portability for convenience.

Which industries use washdown scales?

The food and beverage industry has high standards for hygiene as well as frequent audits. In order to produce the best possible product in sanitary environments, food producers always use washdown scales in production areas as well as other wet areas. The medical and pharmaceutical industries also use washdown scales to maintain clean and sterile conditions. Retail stores that sell food use washdown scales to clean between customers or to avoid cross contamination. Manufacturing facilities, logistics warehouses and construction sites with significant dust and debris use washdown scales given the austere conditions.

Load cell system: electronic versus hydraulic

One of the most important considerations when purchasing a wash down scale is what type of load cell system to get. The two primary washdown scale types have either electronic load cell systems or hydraulic load cell systems.

Electronic load cell system: electronic scales work based on simple strain gauge circuits. These strain gauges are installed inside the load cell body. The load cell connects to the summing card or digital weigh indicator via four conductor or six conductor wire. Components in this system include:

o Load cell(s)

o Electronic cables

o Junction box

o Summing card (PCB)

o Digital weight indicator

Hydraulic load cell system: hydraulic scales work based on hydrostatic pressure. There are no electrical components under the scale. The load cells are connected to a hydrostatic totalizer via stainless steel tubing. The system is pumped with hydraulic fluid and the totalizer converts the pressure to weight via a single strain gauge load cell. Components in the system include:

o Load cell(s)

o Stainless steel tubing

o Hydrostatic totalizer

o Digital weight indicator

In nearly all washdown applications, hydraulic scales are far superior to electronic scales. For starters, the hydraulic scales are completely immune to water damage. To learn more about hydraulic load cells checkout this blog post.

Summary

Washdown scales are great for a variety of reasons – they are built to work in challenging conditions and environments. Their design both improves and speeds up cleaning, keeping the scale reliable. Great clean-up prevents material build up, cross contamination, and growth from mold or bacteria. The IP rating is key to knowing exactly how protected the washdown scale is from water and dust. The folks at American Scale have seen these scales in hundreds of different environments. We’ve seen what works as well as what doesn’t – we are here to help you make decisions regarding your next washdown scale.

Closing Words

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.