SCALING THE DIFFERENCE

Truck scales are designed to weigh trucks and heavy vehicles. A truck scale consists of a foundation, indicator, weighbridge, load cells, junction boxes and any required accessories. Even maintenance requires scale calibration, of both analog and electronic load cells. Each of these components comes in different types and materials depending on your specific weighing needs and environment, but if optimized properly then it will tie your scale system together.

ANATOMY OF A TRUCK SCALE

When looking at a truck scale, they can be broken down into several main components. The foundation, load cell, scale deck, terminal, junction box and cables make up a truck scale. The lifespan of the scale can be upwards of 25 plus years, if properly maintained. The weighing applications used will vary as well, but the process is typically the same. These components are pretty uniform among truck scales, granted there are differences in components (steel or concrete deck, hydraulic or digital load cell, etc). There are also other components that you will need to consider for a truck scale. Categorized as truck scale accessories, you will look at things like a remote display, scale indicators (washdown or stainless steel) or even scoreboards. Component type is entirely up to the preference of the buyer for the customization of the truck scale.

BETWEEN TO WORLDS: PIT OR PITLESS

One of the major parts of a build is the truck scale installation. Scale manufacturers will require you to have some sort of foundation if you are looking to do a full truck scale build. But the first thing you have to get in order is the truck scale foundation. When it comes to different types of truck scales it boils down to two different deck types. These two types are pit style and surface style. A pit scale is built over an excavation, and the surface of the weighing platform is flush with the ground. There was a point in time when all truck scales required pits in order to house the mechanical parts and suspension system. In current day those mechanical scales are being phased out, making pit style an optional choice. A Pitless, or open-sided scale is built up from a grade and have a profile about 28-51 cm. (11-20 in). They may have one or both sides open. The benefit of having an open side scale is that they can be installed rather quickly compared to a pit scale, which will take extra time to pour the concrete and wait for it to cure. Ultimately the decision to go with a pit or a pitless design really comes down to location and preference.

DECK CONSTRUCTION: STEEL VS. CONCRETE

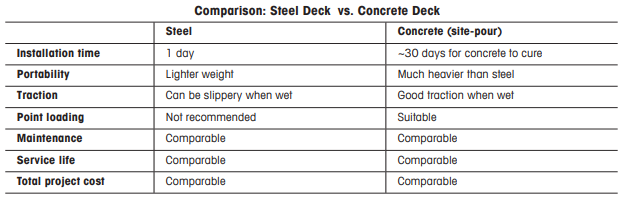

The deck of the weighbridge is a very important part of operating a legal for trade truck scale. The deck is required for you to load the truck onto the scale to be weighed. With most scales, you have your choice of steel or concrete deck surfaces. Steel and concrete decks should provide equal weighing performance because both are built to the same design specifications. However, there are some differences that could make one deck type more advantageous for your site. Below is a chart showing the differences between steel and concrete deck surfaces. For more information regarding the differences with decks, check out our post on steel vs concrete decks.

THE PORTABLE ADVANTAGE

There may be situations where you need to weigh vehicles but only need a truck scale for temporary usage. This is where portable scales come in. Instead of a permanently fixed truck scale, portable scales make use of a steel frame that connects together in sections. The frame includes mounting locations for the load cells on which the deck will sit. For convenience reasons, portable scales will almost always use a steel deck since they are easier to transport. In most cases, the scale is designed to be partially disassembled for relocation simply by unbolting sections of the frame and deck structure. A crane can then be used to lift the sections as needed. Portable scales are a good option if you have a worksite where you are unable to have a permanent truck scale, then going portable may be a good option. If you have more questions on if you need a portable scale, our article “When is a Portable Scale a Good Option” will be a good place to start.

CONCLUSION

Truck scale selection comes in multiple options, but ultimately it comes down to what is the best option that fits you and your work site. Selecting the right scale for your operation will help you avoid common problems that could arrive. Choosing between steel or concrete, pit or open faced or even fixed or a portable scale, there is a bit of configuring required. A thing of note is to look at the manufacturer warranties to see which is the best. At American Scale we strive to bring great information and customer service to our customers. To find more in depth information concerning the turnkey cost, time taken to install or just common issues that show up during ownership. Our Learning Hub has an extensive selection of articles to help you along your journey, including our popular How much do truck scales cost?