In industrial settings where heavy objects need to be weighed, crane scales and dynamometers are two prominent tools used to measure weight accurately and safely. Both instruments play crucial roles in various industries, including construction, manufacturing, shipping, and logistics. Despite serving similar purposes, crane scales and dynamometers possess distinct features and functionalities that make them suited to different applications. In this comprehensive article, we will delve into the intricacies of each device, exploring their differences, advantages, and best use cases.

Crane Scale: The Lifting Weighmaster

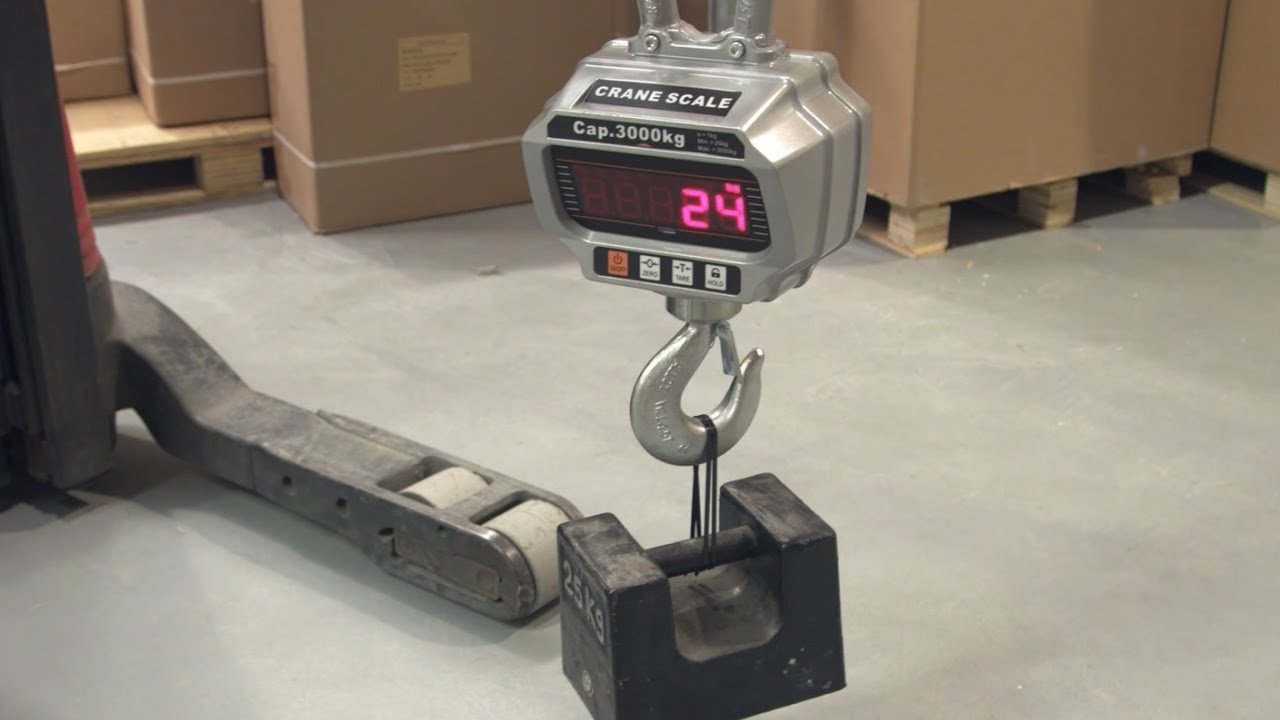

A crane scale is a weighing instrument designed to determine the weight of suspended loads. As the name suggests, it is commonly used in conjunction with cranes or other lifting equipment to weigh objects that are challenging to measure using conventional methods. Crane scales come in various configurations, but most feature a robust hook or shackle for attaching to the load, a digital or analog display unit, and a handle for easy handling.

Key Features of Crane Scales:

Load Capacity: Crane scales are engineered to handle substantial weight capacities, often ranging from a few hundred kilograms to several tons. They are ideally suited for heavy lifting applications in industries like construction, mining, and shipbuilding.

Durability and Safety: Due to the nature of their applications, crane scales are built to withstand harsh conditions and heavy loads. They are often encased in rugged materials, providing protection against impacts, moisture, and dust. Safety features such as overload indicators and safety hooks ensure secure operations and prevent accidents.

Accuracy: High-quality crane scales can deliver precise weight measurements with minimal error. However, factors like sway and motion during lifting can affect accuracy, necessitating proper calibration and skilled handling.

Common Use Cases for Crane Scales:

Material Handling: Crane scales are invaluable in determining the weight of raw materials, equipment, and finished products in manufacturing and construction processes.

Shipping and Logistics: Verifying the weight of cargo before loading onto trucks or ships is essential for compliance with transportation regulations and preventing overloading.

Mining and Heavy Industries: Weighing large extracted materials like minerals, rocks, and ores during mining operations.

Marine Applications: Weighing fish catches, ship cargo, or even dock installations.

Dynamometer: The Force Measurement Expert

A dynamometer, also known as a load cell or force gauge, is a device used to measure the force or tension applied to it. Unlike crane scales, dynamometers are not limited to suspended loads and can be utilized in various configurations, including inline systems and tension measuring setups. They are designed to gauge force in both tensile (pulling) and compressive (pushing) applications.

Key Features of Dynamometers:

Versatility: Dynamometers can be deployed in a wide array of settings, including tension measurement in ropes, cables, and guy wires, as well as compression testing in industrial machinery and equipment.

Accuracy and Sensitivity: High-quality dynamometers offer exceptional precision in force measurement. They can detect even minute changes in force, making them suitable for delicate applications that demand sensitivity.

Compactness: Dynamometers are generally smaller and more compact than crane scales, allowing for easy integration into systems or equipment where space is limited.

Common Use Cases for Dynamometers:

Tension Monitoring: Ensuring proper tension in cables, ropes, and lines for applications like elevators, cranes, and suspension bridges.

Force Testing: Determining the force applied during product testing and quality control in manufacturing processes.

Weight Measurement in Static Environments: Measuring forces in applications where the load is not subject to movement, such as the compression testing of structures or machinery.

Conclusion:

In summary, both crane scales and dynamometers are indispensable tools in the world of industrial weighing and force measurement. While crane scales excel in accurately weighing suspended loads and are often used in conjunction with lifting equipment, dynamometers offer the flexibility to measure forces in both tension and compression scenarios. Understanding the key differences between these two instruments allows businesses to make informed decisions about which tool suits their specific needs best.

Ultimately, the choice between a crane scale and a dynamometer will depend on factors such as the type of application, the weight capacity required, the environment in which they will be used, and the level of accuracy needed. Investing in the right weighing equipment ensures not only accurate measurements but also enhanced safety and efficiency in various industrial operations.