The similarities between Bench scales and floor scales are quite close and in many ways can be interchangeable between the two scales. In the vein that they both are able to be customized with certain features like checkweighing or counting, and have various IP ratings to help both scales withstand the harsh environments and conditions that the scale will have to endure. This article post will discuss the similarities and differences between both bench scales and floor scales, and will lay out which scale will work best for your environment.

Bench Scale Basics

Bench scales are compact scales that are able to be used on a bench or some other sort of raised surface. These scales are very versatile and are equipped with different features like an integrated display or an indicator that can be mounted in different locations. One of the bigger differences between a bench and a floor scale is the maximum capacities that each scale is capable of weighing. Granted a bench scale is smaller and resembles that of a lab balance, it is not nearly as precise as a balance, but does have more precision than a floor scale. Bench scales are typically used for basic production tasks, like check weighing and counting.

bench scale applications

The versatility for bench scales comes into play in the way that it is used for the applications of bench scales. One of the ways bench scales are different from floor scales is in what industries use them. Industries like food services and manufacturing production sites will use bench scales over floor scales to take weight measurements for items like spices, nuts, bolts, etc.

In manufacturing warehouses and factories, bench scales are the common scale of choice. These industries typically will use bench scales for their extremely useful features like counting and checkweighing. Since these particular industries rely on taking repetitive weight measurements, like check weighing and production counting to ensure that the end of production is meeting the requirements to be shipped.

One of the benefits that bench scales have over floor scales is that they have a nice and compact size, that makes the scale easy to relocate and to take a lot of weight measurements without taking up a lot of real estate. When walking into a deli at a grocery store, you will notice that the scale that is used to weigh the produce will most likely be a bench scale with an integrated keypad and indicator. Bench scales are going to be located in environments like manufacturing warehouses, grocery stores and parcel and shipping companies.

bench scale benefits

One of the biggest benefits of selecting a bench scale over a floor scale is the size between the two. Bench scales have a smaller design compared to floor scales, which makes them perfect for environments which have limited space. Places like logistics or shipping companies are going to most likely have bench scales since they take up a very small amount of real estate. Environments that have limited space and locations to place the scale are why bench scales can be a good option due to the small size.

Another benefit that bench scales possess is not only the size but also the layout of the scale. A huge benefit is that bench scales are easily customizable. Due to being easily customizable, bench scales are able to be customized to come in a wide variety of shapes and sizes. This means that you will be able to find a scale to fit any space in your operation. There are a lot of compact scales that are great for basic weight measurements for places like delis and hardware stores. For recording heavier weight measurements you will need something bigger like a floor scale.

Ultimately the benefit of having a bench scale over a floor scale is the ability to have multiple size options and keep a relatively small footprint. They are good for recording low to moderate size weight samples. Think about your industry and the type of weight measurements that will mainly being recorded. These things will help you decide if a bench scale is the right choice for you.

What is a floor scale?

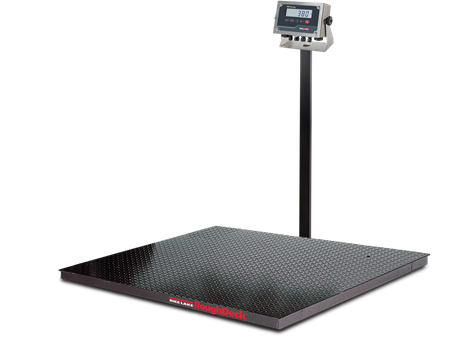

A floor scale is a type of scale that can be used on the floor. The floor scale typically has a higher maximum capacity over a bench scale but does not offer extremely high capacities compared to platform and forklift scales. The design of a floor scale has the ease of use in mind. They are usually equipped with a large weighing platform (some with a high IP rating for washdown environments) to handle a larger quantity of items being weighed. They also tend to come equipped with detachable indicators and keypads to make it easier to record measurements. Floor scales are a good choice for industries that require a higher weight capacity and are ideal for weighing operations that weigh bulky and large items.

floor scale applications

When it comes to design versatility and durability, both bench and floor scales are very similar in what they offer to the production process. Floor scales will most likely be located in both commercial (logistics, hardware, etc) and industrial environments. The environments that use floor scales tend to take heavier weight measurements due to weighing large and bulky items compared to bench scales. Another plus is that floor scales are highly customizable and can be equipped with certain features such as counting and checkweighing. These features are able to serve as an efficient way to check inventory and make sure packages are the proper weight at the end of production.

You will also see floor scales in industries like farming and even scrap yards. They are good for weighing heavy items, such as animal feed or crates filled with scrap. These industries use these scales because of how durable they are. Most floor scales will come with a high IP rating to offer extra protection from the harsh environments that the scales operate in.

floor scale benefits

The biggest benefit that a floor scale has over a bench scale is the fact that it has a way higher capacity over a bench scale. The reasoning for this is because they are designed to take weight measurements from objects that are a lot heavier and bulkier compared to objects weighed on a bench scale. The load cells used in a floor scale have a much higher maximum capacity, which can weigh items exceeding weights over 1200lbs. This aspect makes floor scales a prime option for industries like manufacturing and warehouses. Floor scales have the benefit of having ease of use in mind for those taking the weight measurements. Being able to lift heavy, bulky items on the floor scale makes the entire process a lot simpler for those who are taking the weight measurements.

Conclusion

Bench and floor scales are commonly used in industries such as agriculture, retail and manufacturing businesses. Depending on what you are weighing and how often will help you decide if your operation needs a bench scale or a floor scale. Head over to our Learning Center to check out articles on things to consider when selecting a floor scale and how to choose a bench scale. These are great resources to give more insight into what is needed for the right scale for the right operation.