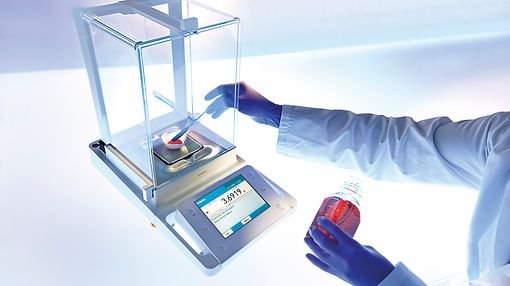

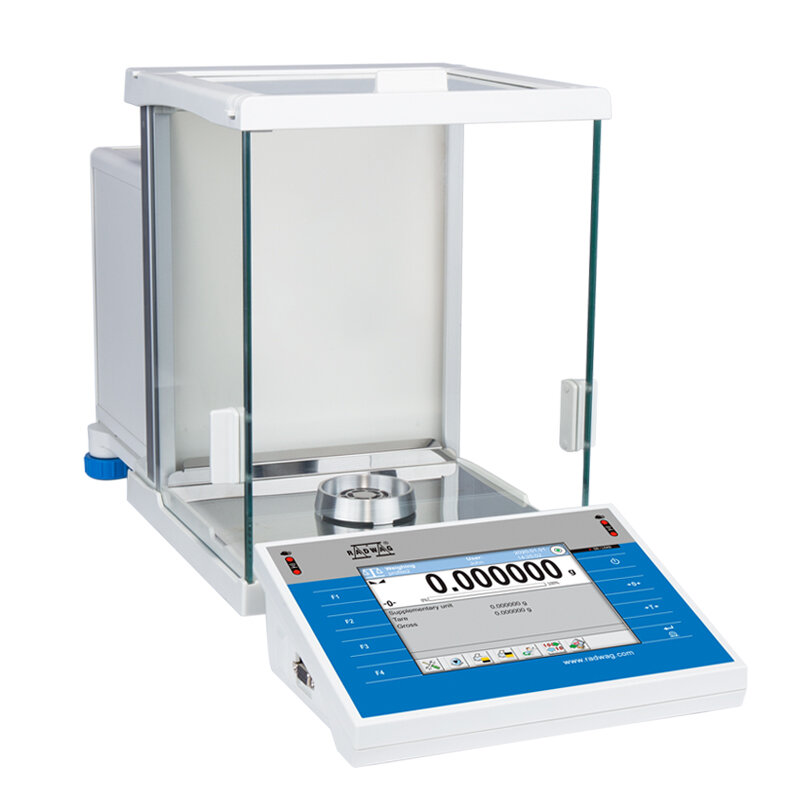

Laboratory balances are precision instruments used in laboratories to measure the mass of substances with high accuracy. These delicate scales require regular maintenance to ensure their optimal performance and reliability. Proper maintenance not only extends the lifespan of the analytical balance but also ensures accurate and consistent measurements.

In this article, we will walk you through the step-by-step process of performing maintenance on an analytical balance.

Understand the Basics

Before diving into maintenance procedures, it's important to have a clear understanding of how lab balances work. These balances operate on the principle of a beam and counterbalance, with a highly sensitive weighing pan. Even minor environmental factors, such as air currents and temperature fluctuations, can affect their accuracy. Therefore, maintaining a stable and controlled environment is the first step in ensuring accurate measurements.

Regular Cleaning

A clean analytical balance is essential for accurate measurements. Dust, debris, or residue can accumulate on the weighing pan and affect the balance's sensitivity. Follow these steps for regular cleaning:

Power Off: Ensure the balance is turned off before cleaning to prevent any electrical hazards.

Remove Residue: Use a soft brush or a lint-free cloth to remove any residue from the weighing pan and surrounding areas. Be gentle to avoid damaging sensitive components.

Use a Mild Cleaner: If necessary, use a mild cleaning solution recommended by the manufacturer to clean the weighing pan and other surfaces. Avoid harsh chemicals that could damage the balance.

Clean Draft Shield: If your balance has a draft shield, clean it regularly to prevent dust from settling on the weighing pan.

Calibration

Regular calibration is crucial for maintaining the accuracy of analytical balances. Calibration compensates for any drift or changes in the balance's performance. Follow these steps for calibration:

Use Standard Weights: Obtain a set of certified standard weights appropriate for the balance's capacity.

Pre-warm the Balance: Turn on the balance and allow it to stabilize for at least 30 minutes before calibration.

Perform Calibration: Follow the manufacturer's instructions for calibration. Typically, this involves placing the standard weights on the weighing pan and adjusting the balance until the displayed weight matches the known weight of the standards.

Record Calibration Data: Keep a record of calibration results, including the date, standard weights used, and any adjustments made.

Environment Control

Maintain a stable environment to minimize external factors that can affect the balance's accuracy:

Temperature Control: Keep the laboratory at a consistent temperature to prevent thermal expansion or contraction of components.

Minimize Air Currents: Analytical balances are sensitive to air currents. Place the balance away from doors, windows, or areas with high traffic to minimize the impact of air movements.

Note: Because the load cell in lab balance is delicate, be mindful of applying any pressure to the weigh plate. Since those load cells are only able to handle a certain capacity, you could run the risk of damaging the load cell if added pressure is applied.

Routine Inspection

Perform routine inspections to identify any signs of wear, damage, or malfunction:

Check Seals and Gaskets: Inspect seals and gaskets for signs of wear or damage. Replace them if necessary to maintain the balance's integrity.

Inspect Cables and Connections: Check cables and connections for any signs of fraying or damage. Ensure all connections are secure.

Verify Display Readouts: Regularly verify that the display readouts are clear and accurate. If there are discrepancies, investigate and address the issue promptly.

Professional Service

While regular maintenance can address many issues, it's essential to schedule professional servicing at regular intervals. Professional technicians can perform more in-depth inspections, identify potential problems, and address issues that may not be apparent during routine maintenance.

Companies like American Scale offer various services when it comes to maintaining your scale. The advantage of going to a professional service, is that you have the benefit of having state certified scale technicians perform service on your scales, thus making them state compliant.

Conclusion

Maintaining an analytical balance requires a combination of regular cleaning, calibration, environment control, routine inspection, and professional servicing. A well-maintained analytical balance not only ensures accurate measurements but also contributes to the longevity of the instrument. By following these comprehensive maintenance steps, laboratories can optimize the performance of their analytical balances and enhance the reliability of their analytical results.

American Scale is your source for industrial scales. Be sure to check out our Learning Hub for in depth articles tackling multiple topics. From scale service and maintenance, to learning how to pick the right scale for you. American Scale has you covered.