Beginners Basics

As you start searching for the right floor scale system, there are a few things you may want to consider before deciding on a floor scale to buy. Some of the things that you may want to consider is whether the scale you want will be legal for trade or not. What is the area you will weigh look like, and does the size of the scale suit the area the scale will be installed in? This post will break down the basics of floor scale ownership and help guide you towards purchasing a quality scale that will fit your weighing needs.

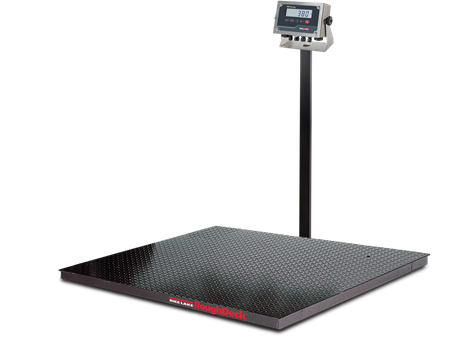

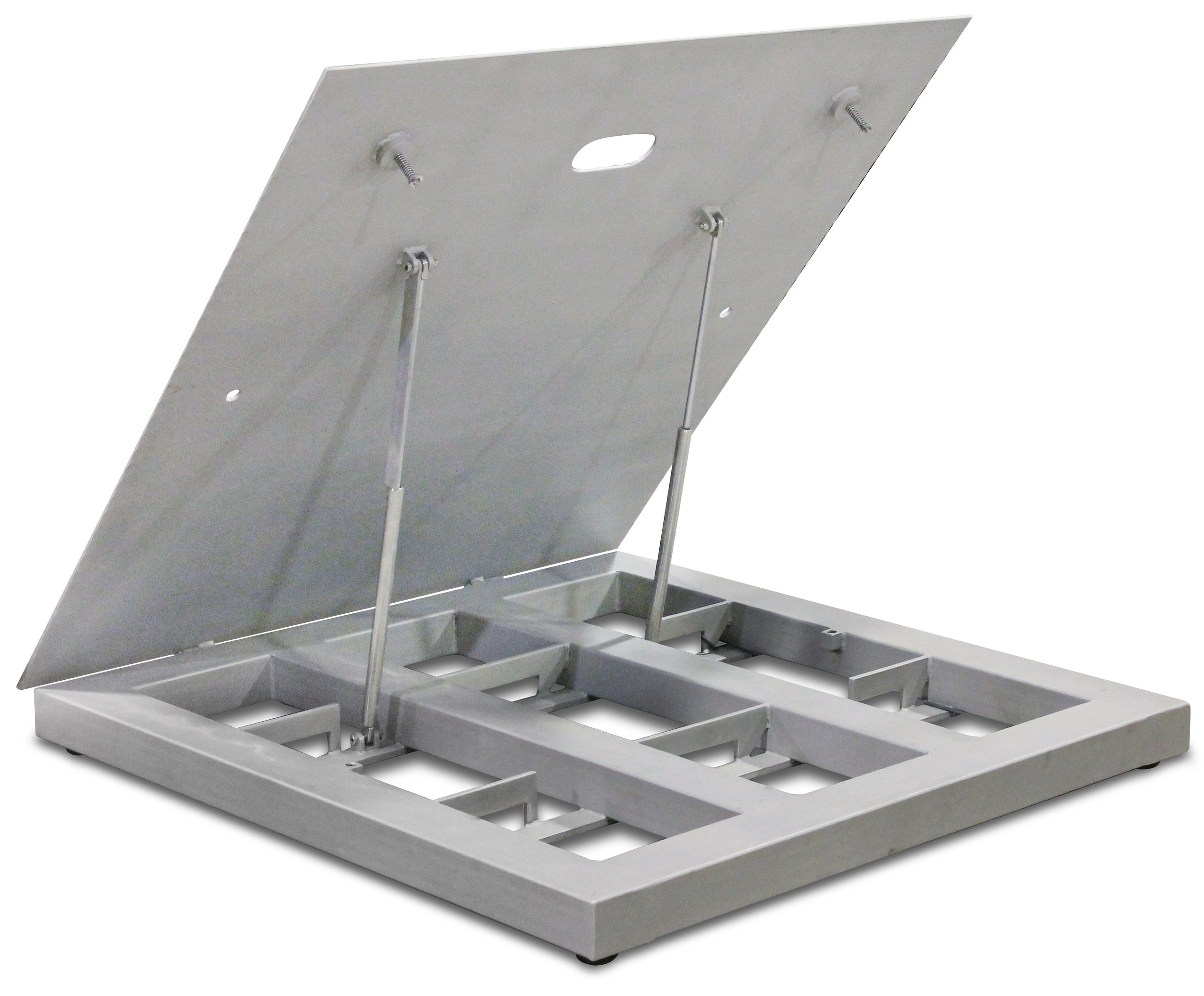

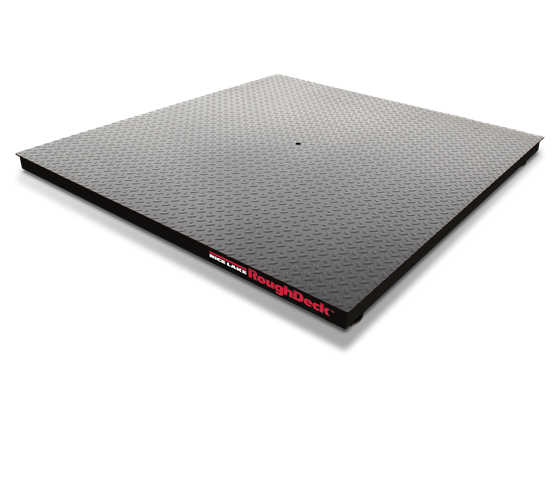

The basic floor scale consists of a scale platform which usually has a tread plate on the surface along with four electronic load cells (shear beam) underneath the deck. The load cells underneath the deck are then connected to a J box or junction box inside. The junction box allows each load cell to adjust each load cell under the platform to ensure that they all record the same weight. From the j-box is a cable that connects to the scale indicator. The majority of floor scales will most likely be painted steel. There are stainless steel variants for floor scales, but those are usually used in washdown environments and tend to have a higher price tag. Scale calibration on a floor scale is the same principle, just with different capacities depending on the weighing applications.

WHERE TO START?

Understanding where to start when searching for a floor scale can be an overwhelming ordeal, it can be a bit simpler if you know where to start. The fact is that there are a lot of factors you should consider when choosing what type of scale to buy. Do you want scale accessories? Will your environment have a remote display or scoreboard? These are questions you would want to consider when pricing your floor scale. The easiest way to determine this is to evaluate what you are using the scale for. This means that you should consider the environment the scale will be in. Will the scale be in a factory where there will be a lot of dust and debris floating around? Are you wanting analog or digital? Will you be weighing heavy materials? These questions are what need to be asked to help guide you toward the best suitable floor scale for your operation.

WHY GO FLOOR?

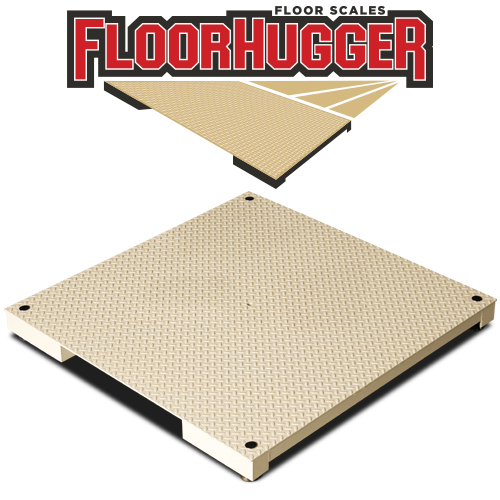

Specific scenarios call for specific tools, and when it comes to scales, you want the right scale for the job. Floor scales are a great choice for environments that require you to weigh large, heavy and bulky items. The reasoning for this is because the platform of a floor scale is quite literally on the floor, thus making weighing large and heavy items a lot easier. In environments like industrial factories, manufacturers and scrap yards will most likely have a floor scale, due to the heavy items being weighed. Floor scales are able to be installed on a flat or level surface or it can be installed in a “pit” style, where the scale will sit in the ground a bit. If your operation requires a scale that can handle higher weight and can stand up to the hazards of the environment, then you will want to go with a floor scale.

DETERMINING THE RIGHT SCALE

Knowing what you are generally going to weigh can help you determine the size and shape of the scale you want. It is one thing to weigh rectangular boxes all day, but often enough you will weigh different sized and shaped items, so having a platform size large enough to accurately weigh any of the items you receive.

The key to ensuring you have an accurate scale is making sure that the weight capacity has a good enough range, and that the scale is positioned in a way that it won’t feel vibrations or any other hazards that could cause you to have an inaccurate measurement. The first step you will want to do is figure out what the typical sizes and shapes of the items you will be weighing, so it can help you decide what scale size will be needed.

Keep in mind that certain types of floor scales will be better suited for certain environments. Usually equipped with a steel deck for heavy duty. Scale manufacturers will usually have different features for different scale models. A good example of this is when you have a floor scale in an environment that is considered a washdown environment. This means that the environment in which the scale is located is subjected to being sprayed or “washed” down by a power washer. The components on a washdown floor scale will Understanding this will help you to avoid purchasing the incorrect scale.

CONCLUSION

The best floor scale for you should be reliable and accurate, providing increased uptime and greater productivity. The amount of industries that legal for trade bench scales are used far exceeds what is listed in this article. The floor scale is a very versatile scale and due to its versatility they are able to service multiple industries and provide accurate weight measurements. Keep in mind that these tips should help increase the lifespan of your scale. At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our truck scale articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership. Also, take a look at our“Common Problems With Bench Scales'', which can help give insight to what issues could arise while owning a bench scale.